The First-Time Fix – a Top KPI for a Service Business

Do you track your field service’s first-time fix rate? Do you consider it a key performance indicator (KPI)? If so, you are in the top...

Apr 14, 2024

# of Minutes to Read

Do you track your field service’s first-time fix rate? Do you consider it a key performance indicator (KPI)? If so, you are in the top tier of service business managers. Or do you measure field service performance in response time and jobs scheduled? If so, it is time to revisit your strategy.

Why is First-Time Fix so Critical?

The number one customer complaint regarding a service call is failure to resolve the issue. (Aberdeen Group, First-Time Fix, a Metric that Drives Success)

If your field unit doesn’t bring the expertise, equipment or parts needed to resolve the issue, it means a a second call and an unsatisfied customer. Consider the impact of that outcome.

Consequences of failure to resolve an issue on the first service call

Cost to your company of a second visit. What does it cost your company to roll a truck to an address? That will depend on your industry, but many service businesses report a cost per visit of about $200. Can you really pass that entire cost on to the customer? Probably not, in which case it will represent a productivity loss.

Loss of future revenue. The customers’ disappointment will reduce repeat business, the lowest-cost way to grow your customer base. Negative customer reviews, online and word of mouth, will raise the cost of new customer acquisition.

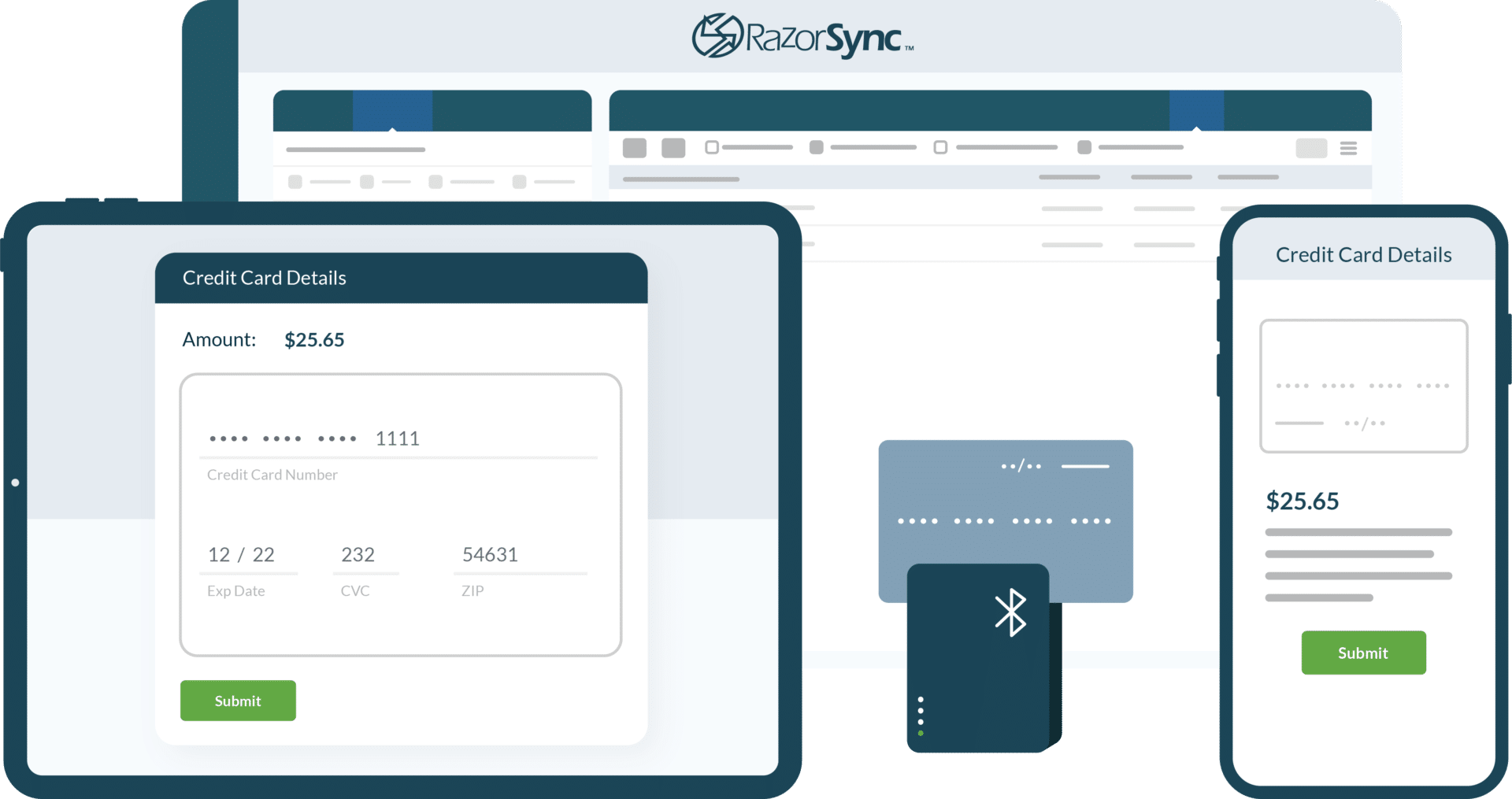

Reduced capacity and efficiency. A field unit tied up with a second service call will not be available for a new job. More back-office time will be required for bookkeeping, and front-office staff will spend more time on customer communications.

What Does it Take to Have an Excellent First-Time Fix Rate?

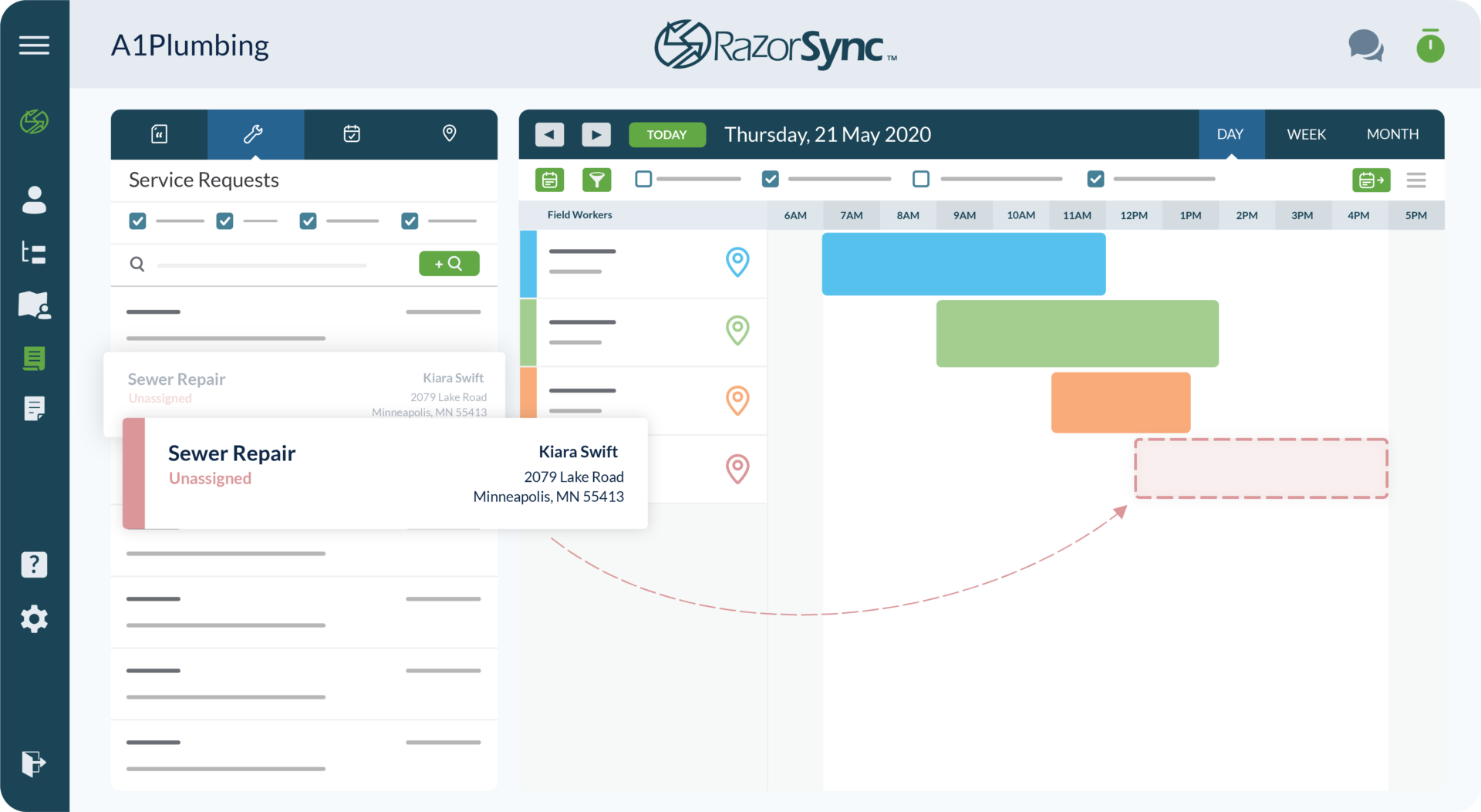

If you are going to minimize the losses discussed above, the first unit to respond to a service request needs to have the expertise, technology, parts and access to support to resolve the issue. Optimizing your first-time fix rate requires organizational buy-in on operational best practices and an investment in mobile service technology.

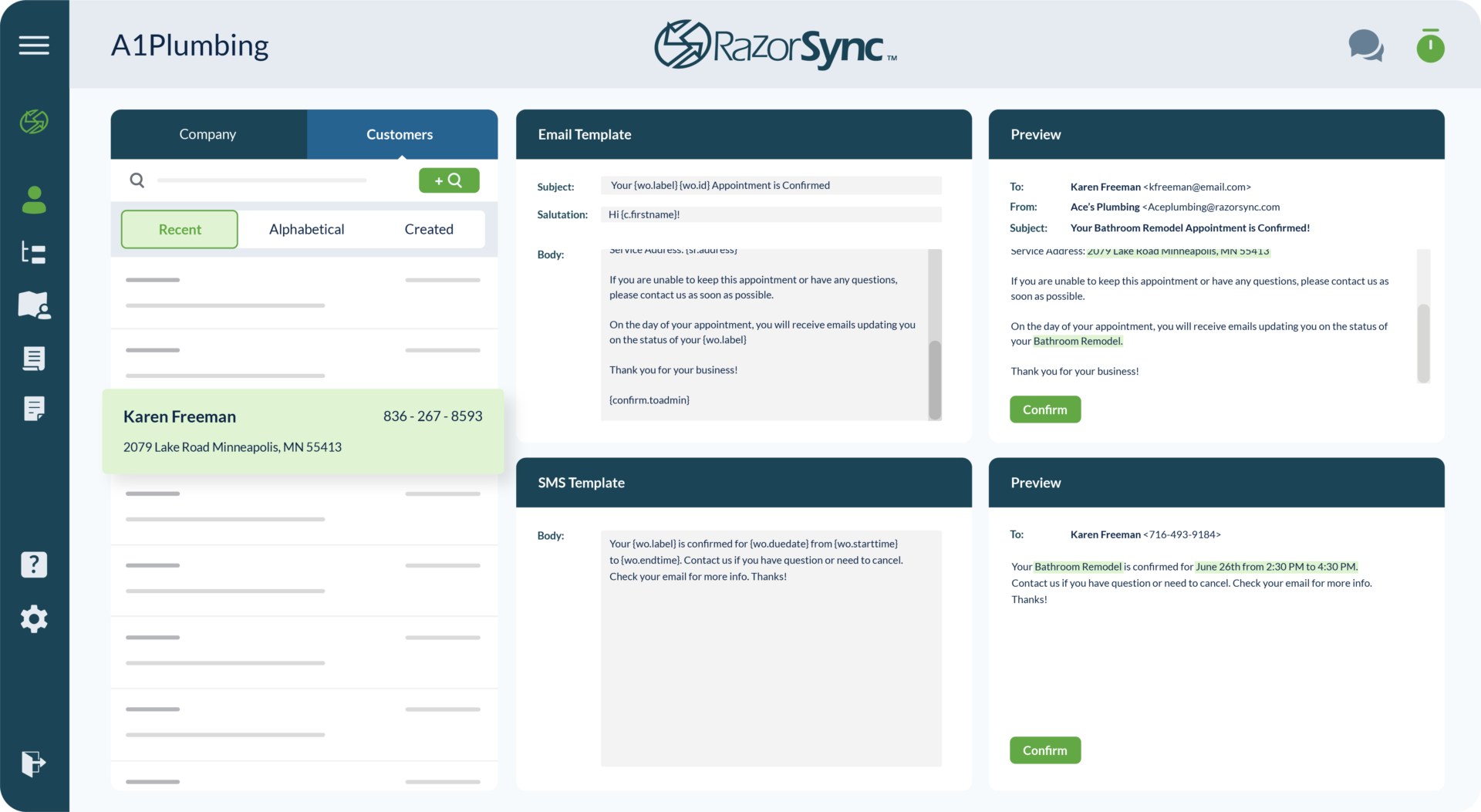

The first step of course, is to collect as much information as possible on the service request. This could include model and serial number of an appliance, photos of a furnace install and a detailed description of the malfunction or requested upgrade. If you have a self-service customer portal, customize the service request form to collect all pertinent information. When a service request is taken over the phone, your office staff should be able to contact field staff immediately if necessary to collect the information.

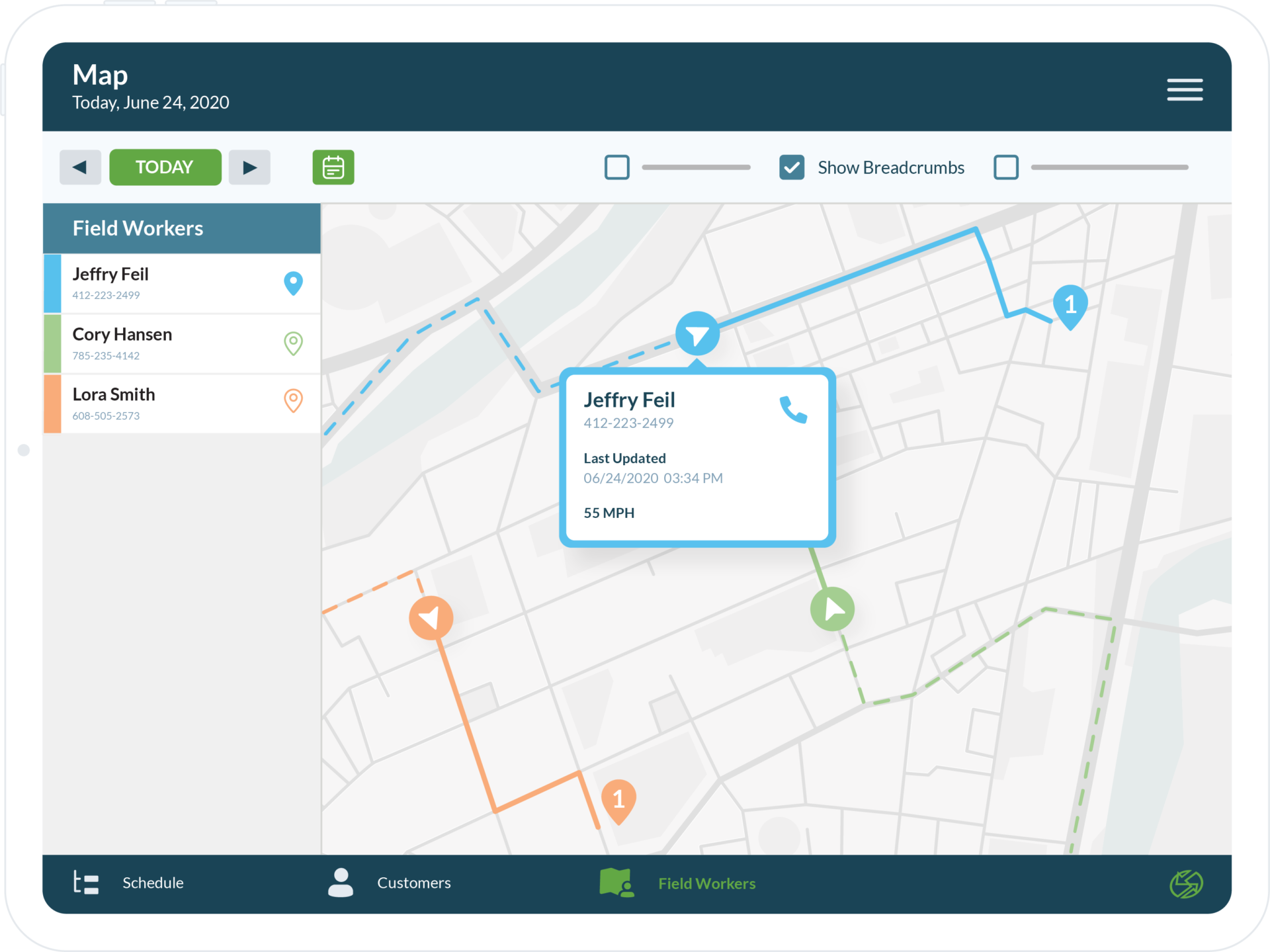

Provide your schedulers with specific information on technicians’ qualifications and experience. If your scheduling software allows, color code technicians to ensure the team member scheduled has the right training and experience.

Analyze parts ordered over a year’s time, then develop a plan to stock or have immediate access to commonly needed parts. A technician should review the service request and check to see that the truck is stocked with likely parts. If necessary, deliver a part to a technician at the job site. (Don’t overlook the benefit of empowering field technicians to sell upgrades onsite.)

Provide master and journeyman technicians with mobile devices that allow them to communicate from the field, and to download manufacturer information with ease.

If a second or later visit is necessary, be alert to the opportunity to improve your reputation for good service. Train your employees to express concern and consider offering the customer a discount on the next service.

Make First-Time Fix a Team Goal

Track your company’s progress, as a whole or by team, from month to month. Post results on the wall. Congratulate employees one-on-one and as a team for improvement. Keep an eye on customer reviews and comments – these are an indicator of true success.